Surveillance capsule testing

Surveillance capsule testing is a critical part of the nuclear industry's safety management, mandated under 10 CFR 50 Appendix H and detailed in ASTM standard E 185. Most nuclear power plants globally are required to implement a Reactor Pressure Vessel (RPV) surveillance program from the outset of plant operation. Depending on the reactor type—typically three capsules for Boiling Water Reactors (BWRs) and five for Pressurized Water Reactors (PWRs)—these capsules are strategically positioned in the downcomer near the vessel’s inner diameter surface. The capsule contents include neutron dosimeters, tensile specimens, Charpy specimens, and occasionally fracture toughness specimens, all designed to monitor the integrity of the reactor’s pressure vessel over time. These capsules are periodically retrieved and analyzed to evaluate the extent of neutron-induced damage to the RPV, helping predict the material's behavior and structural integrity. MPM not only measures the Charpy impact energy, but MPM’s instrumented striker technology provides the load-deflection data needed to measure fracture toughness directly. This technology offers the potential for significant margin reduction in PT curve calculations since the current approach of shifting the ASME KIR curve by the Charpy shift is very conservative.

MPM’s surveillance testing program

We operate a comprehensive surveillance testing program under a strict Department of Environmental Protection (DEP) radioactive materials license. This program is a cornerstone of our commitment to supporting the nuclear industry's safety and operational reliability. The services offered under this program include:

Logistical support: MPM provides custom-designed shipping containers and handles all shipping logistics from the nuclear plant site to our laboratories, ensuring safe and compliant transport of radioactive materials.

Documentation preparation: Our team prepares all necessary shipping documentation, adhering to regulatory standards to ensure compliance and security during transit.

Capsule processing: On arrival at our facility, each capsule is meticulously opened, inventoried, and the specimens within are cleaned and prepared for testing and analysis.

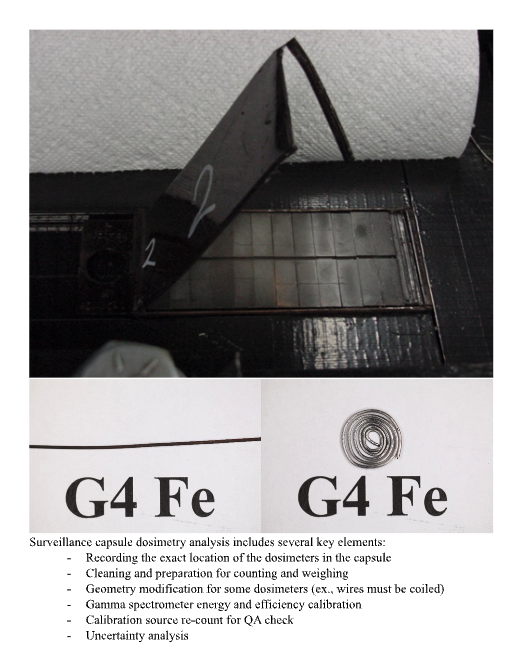

Dosimetry analysis: We perform state-of-the-art gamma spectroscopy to ascertain the specific activities within the capsule, which provides essential data on the radiation exposure of the specimens.

Neutron transport analysis: Our 2D/3D transport methodology is fully compliant with Regulatory Guide 1.190, offering a detailed understanding of neutron fluence in the active fuel region, as well as to reactor components above the top of active fuel (TAF) to below active fuel (BAF). MPM has developed an advanced steam density distribution model for analysis of Boiling Water Reactors (BWRs) above TAF.

Mechanical property testing: We conduct comprehensive tests on the mechanical properties of the materials, including Charpy impact, tensile strength, and fracture toughness assessments. These tests are critical for understanding the material's resilience and response to prolonged radiation exposure.

Waste management and disposal: Following analysis, MPM handles the disposal of radioactive waste materials in accordance with all regulatory guidelines, ensuring environmental safety.

Specimen storage: NRC requires long-term storage of broken Charpy specimens throughout the life of the power plant. Optionally, we provide secure, long-term storage of tested specimens for future reference or further analysis.

Pressure-temperature (P-T) curve calculation: Critical for ensuring operational safety, our P-T curve calculations help define the operational limits of the reactor pressure vessel under varying conditions, based on the surveillance data.

MPM has one of the only HA private hot cells in the US. Here, the EDM machine with a radionuclide filter for machining radioactive test specimens.